Mold and Die Components, Mold and Die Tooling - Custom

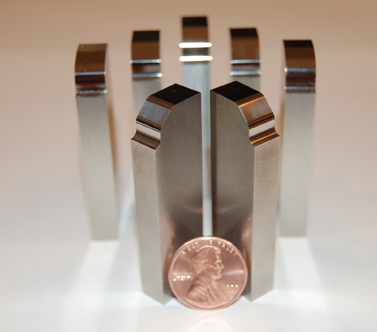

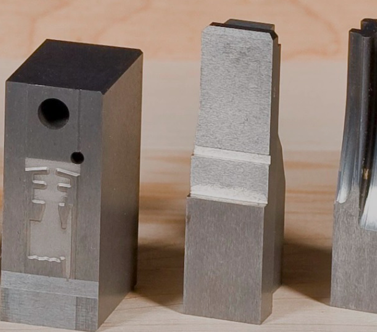

Ramtec delivers custom die and mold component solutions with optimal efficiency, streamlining innovative in-house processes since 2000. Tight tolerances can be held down to .0001 inches with ultra precision surface finishes.

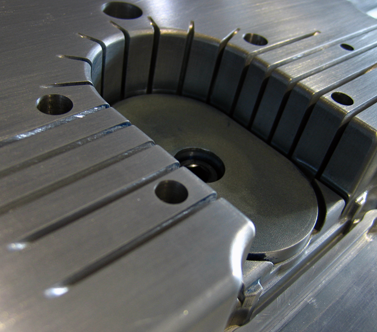

Ramtec is a true custom manufacturer combining unique manufacturing know-how across several manufacturing processes with a strong commitment to quality. These are in support of our customers in the metal stamping die, plastic injection mold, die cast, and forging industries.

All die and mold part tooling is custom to your specification, with nothing standard. We can produce a wide range of variation in thicknesses, lengths, widths, heights, part weights, tolerances, and die clearances. Our tooling holds up under the challenge of significant wear resistance.

-

Part Length Max. 36 in.

-

Part Width Max. 24 in.

-

Part height Max. 8 in.

- Cavity/Core Blocks for Molds

- Mold Inserts

- Stamping Die Inserts

- Die Punches

- Trim Sections

- Pins

- Strippers

- Wear Parts

- Perishable Tooling

- Punch Holders

- Form Inserts

Worldwide Service

Various grades & sizes that are pre-hardened, is always in-stock to ensure smooth workflow for us and our customers. If you need a broken die or mold part repaired or replaced quickly.

Materials:

- Carbide

- Tool Steels: A2, D2, S7, H13, CPM-10V

- Aluminum

- Carbon Steel

- Stainless Steel

- Graphite

Industries:

- Electrical Connector

- Die and Mold

- Consumer Products

- Medical

- Automotive

- Special Machine

View Our Manufacturing Facility

We utilize state-of-the-art equipment and the latest technology.