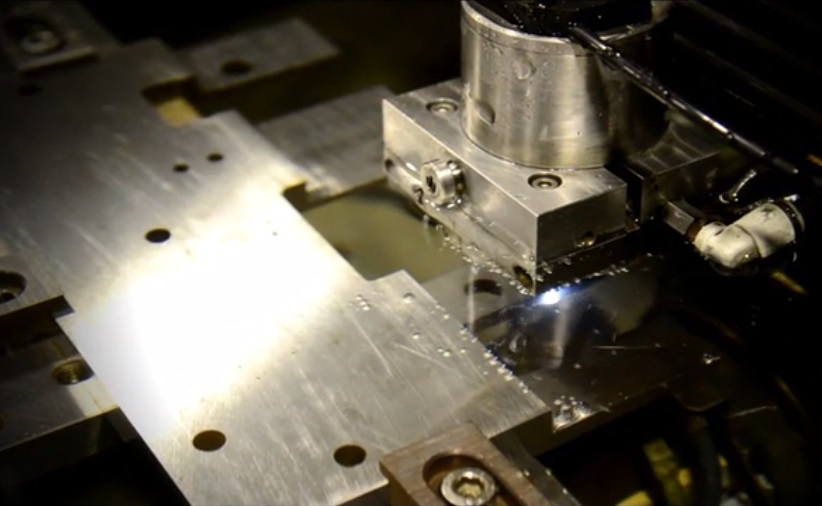

Wire EDM Services

Specialists in 4-Axis Wire EDM, High Precision, Close Tolerance

Ramtec 4-Axis capabilities allow us to hold extremely tight tolerances (+/- .0001), but yet can be extremely cost effective for short-run production. Complex shapes can be cut from difficult to machine materials. Also, traditional machining and cutting are often limited to softer materials whereas wire EDM can cut through hardened materials without sacrificing tolerance. Custom tooling is generally not needed.

Wire EDM varies slightly from conventional EDM as the spark produced in wire EDM always takes place in deionized water (the dielectric used for Wire EDM processes). Wire EDM can provide high dimensional accuracy for close fitting parts. The process can make sharp inside corners and can cut material thickness form only a few thousands of an inch to several inches. View our punch and die tooling and mold component sample parts below.

Ramtec has the complete package necessary to deliver on any wire EDM project - one time or on a long-term basis. Our wire EDM equipment allows us to perform simultaneous operations and minimize turnaround time. Combined with our 30 years of manufacturing know-how, this equipment investment has allowed us to deliver on the precise and cost-effective wire EDM services that we claim. Take a panoramic tour of our facility found below.

On-time delivery is assured and rush orders delivered within 24 hours, if necessary.

Other Sample Tooling:

All tooling is custom to your specification, with nothing standard. We can produce a wide range of variation in thicknesses, lengths, widths, heights, part weights, tolerances, and die clearances. Our tooling holds up under the challenge of significant wear resistance.

- Punches

- Trim Sections

- Pins

- Strippers

- Wear Parts

- Perishable Tooling

- Punch Holders

- Form Inserts

- Other Die and Mold Components

Quality Integrated In Our Processes

Ramtec is an ISO 9001:2015 certified manufacturer employing state-of-the-art quality inspection technologies and techniques in our facility. We maintain complete in-house responsibility for our high quality standards. "100% Made in the USA" Quality is integrated into every part that we produce.

Various grades & sizes that are pre-hardened, is always in-stock to ensure smooth workflow for us and our customers. If you need a broken die or mold part repaired or replaced quickly.

Materials:

- Carbide

- Tool Steels: A2, D2, S7, H13, CPM-10V

- Aluminum

- Carbon Steel

- Stainless Steel

- Graphite

Industries:

- Electrical Connector

- Die and Mold

- Consumer Products

- Medical

- Automotive

- Special Machine

View Our Manufacturing Facility

We utilize state-of-the-art equipment and the latest technology.